- Roll Cooling Spray Systems

- Hengzhong Catalogue

- Aluminum Casting roller

- Aluminum Casting roller shell

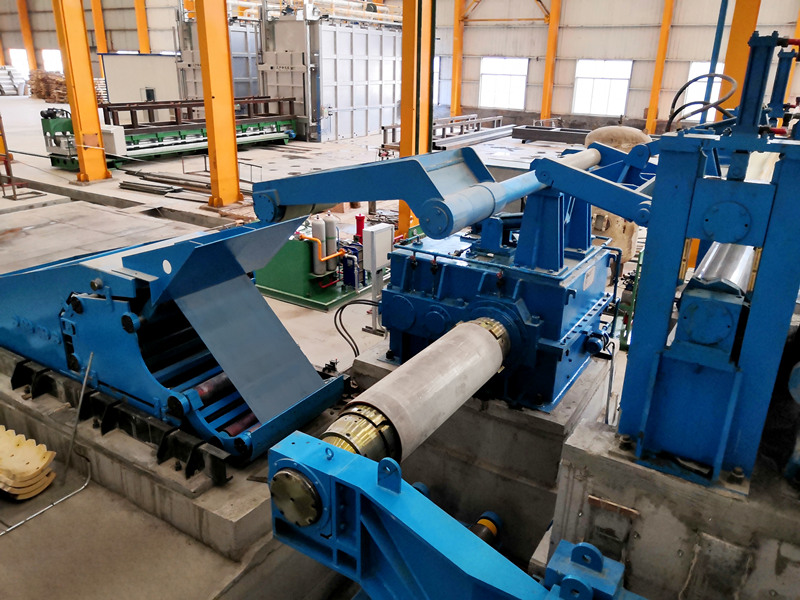

- Aluminum casting mill

- Aluminum foil rolling mill

- Aluminum Cold rolling mill

- Mold Crystallizer aluminum for continuo

- Cut to length line

- Tension leveler line

- Aluminum coil Edge trimming of rewinding

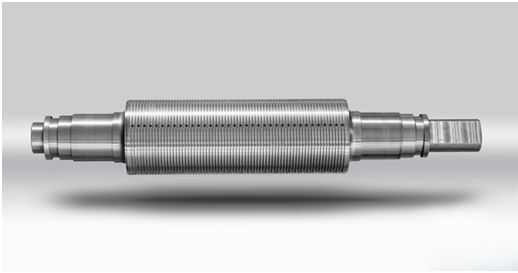

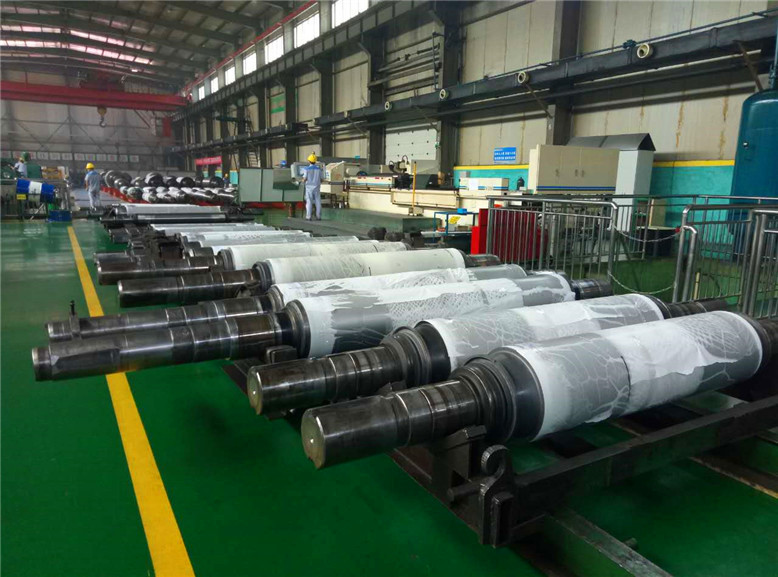

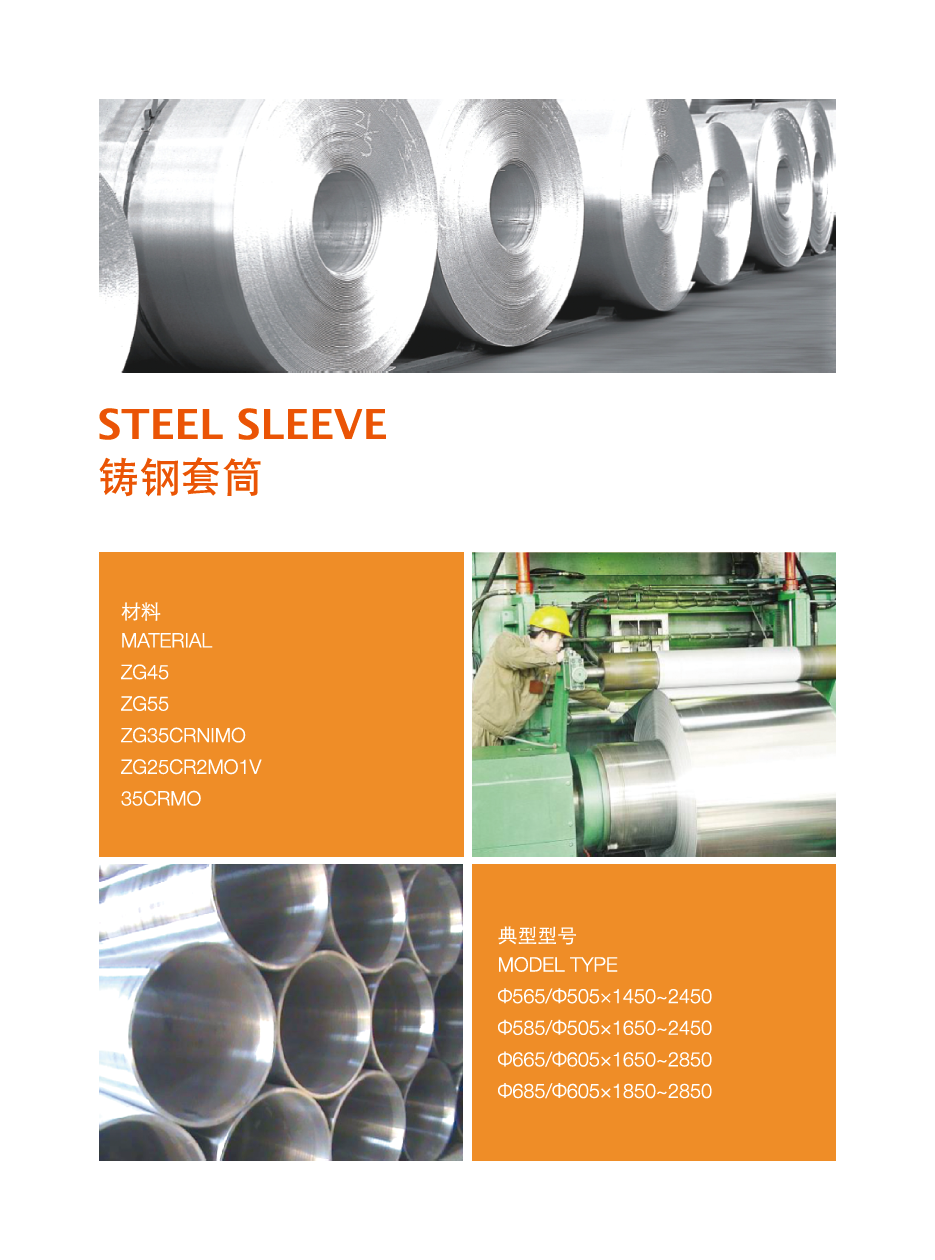

- Roll sleeve for aluminum coil

- Roller shell for cast rolling mill

- Color Aluminum Reflective sheet

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:23-02-14 Glance Over:

Decorative foil is a decorative material applied in the form of aluminum-plastic composite. It has the advantages of heat insulation, moisture resistance, sound insulation, fire prevention and easy cleaning. It also has a luxurious appearance, convenient processing, and fast construction and installation. At present, my country's construction and home improvement industries have formed an upsurge in the application of decorative foils. With the rapid development of my country's construction industry and the continuous popularization of decorative foil applications, the demand for decorative foil will increase significantly. In recent years, the demand has increased sharply. It is generally used as decorative materials for the inner walls of buildings and indoor furniture. , It is also widely used in the facade and interior decoration of commercial institutions . The thickness is usually: 0.01-0.2mm .

Ø Decorative aluminum foil production process plan

Aluminum alloy smelting - degassing - casting rolling - homogenization - cold rolling - intermediate annealing - cold rolling - intermediate annealing - tension leveling line - finishing slitting - inspection - packaging

The decorative aluminum foil produced by this technological process :better plate shape, easy rolling, uniform surface, qualified quality and fast speed.

Aluminum alloys for decorative foils are prone to process cracks during the casting rolling process, and the cracks expand during cold rolling, and the strips are easy to break. The segregation phenomenon is serious in the casting rolling production process. Therefore, in the casting rolling production process, the chemical composition of the alloy and the parameters of the casting and rolling process must be strictly controlled in order to obtain a good casting and rolling slab. During the rolling process, pay attention to collecting and organizing relevant rolling parameters, such as roll temperature, rolling oil temperature, pass processing rate, rolling speed, ambient temperature, etc. So as to realize the precise management of product data.

Plate shape is one of the key factors in the production of decorative aluminum foil. The stretch bending straightening machine equipment produced by our company has gradually mastered reasonable pass processing, reasonable rolling lubrication, and reasonable roll shape through repeated trial production. Control and reasonable operation methods make the aluminum strip produced by it have good shape and uniform surface. High customer repurchase rate.

Compared with the hot rolling method, the decorative aluminum foil produced by the casting and rolling process meets the quality requirements of users, and the production cost is lower than that of hot rolling, the production cycle is short, the yield is high, and the economic benefits are considerable. The decorative aluminum foil produced meets the quality requirements of users.

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL: +008615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp : +008615188318176 Wechat : +008615188318176