- Roll Cooling Spray Systems

- Hengzhong Catalogue

- Aluminum Casting roller

- Aluminum Casting roller shell

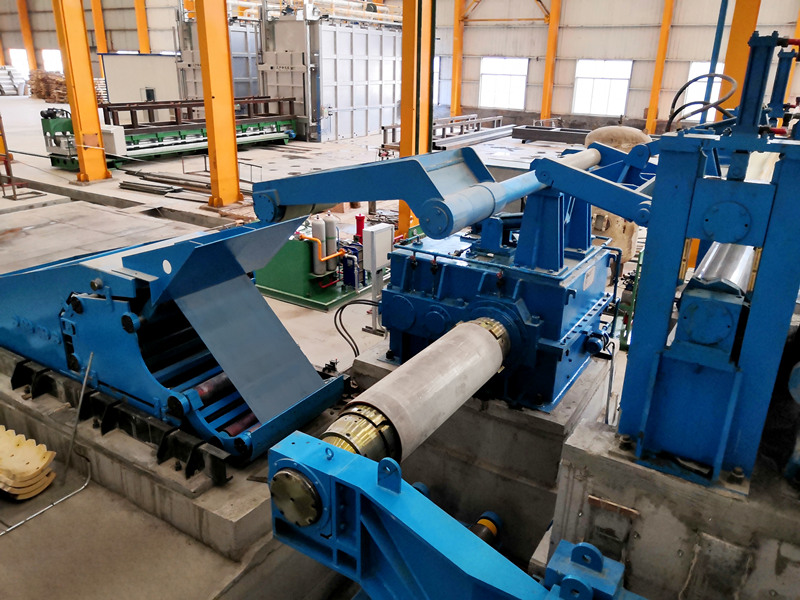

- Aluminum casting mill

- Aluminum foil rolling mill

- Aluminum Cold rolling mill

- Mold Crystallizer aluminum for continuo

- Cut to length line

- Tension leveler line

- Aluminum coil Edge trimming of rewinding

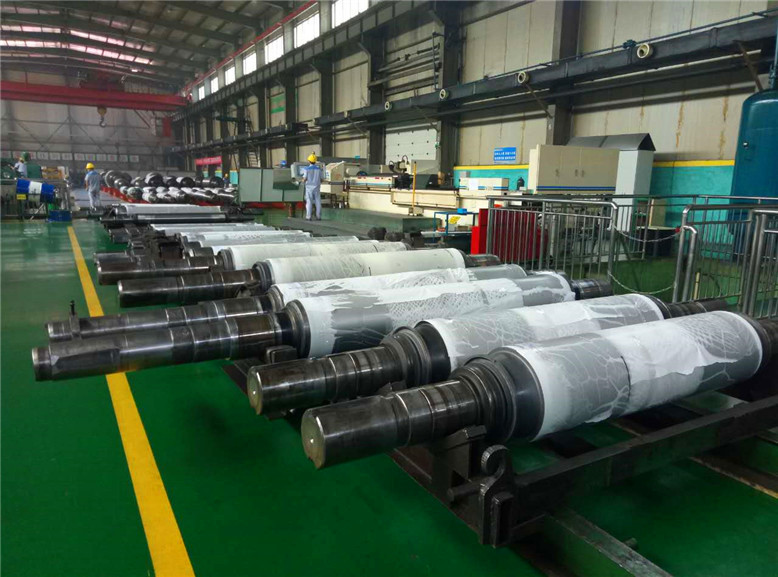

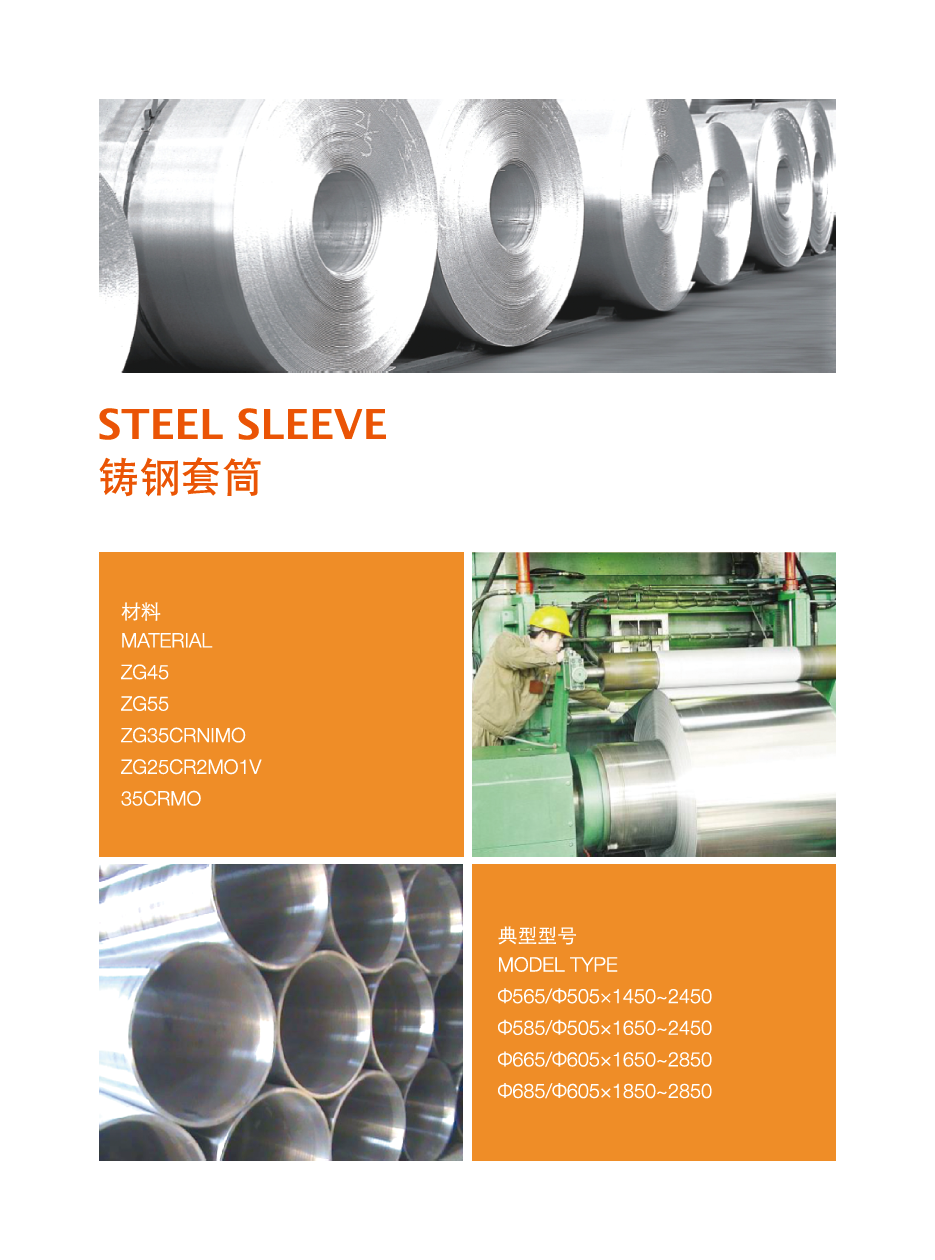

- Roll sleeve for aluminum coil

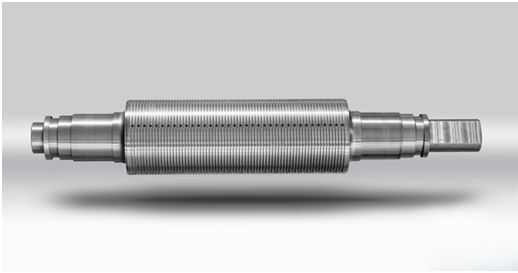

- Roller shell for cast rolling mill

- Color Aluminum Reflective sheet

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:22-11-16 Glance Over:

power batteries

The anode of the lithium battery of electric vehicles needs aluminum foil, and the development goals of electric vehicles are energy saving, automation and unmanned driving. The preferred material for lightweight of automobile, therefore, aluminum plays a crucial role in the development of new energy vehicles.

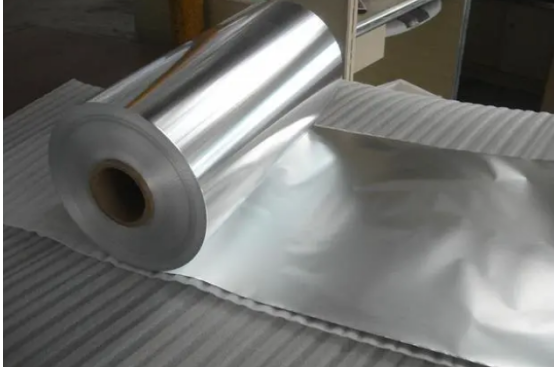

Battery aluminum foil refers to the aluminum foil used for the positive electrode material of lithium ion battery, or the aluminum foil for lithium battery current collector, which belongs to the finishing product in the aluminum foil product series. The thickness of rolled aluminum foil varies from 0.01-0.05mm. Commonly used lithium battery pure aluminum foil has various alloy grades such as 1060, 1050, 1145, 1235, etc., and has states such as O, H14, H24, H22, and H18 .

The basic structure of a lithium battery includes a positive electrode, a negative electrode, an electrolyte, and a separator. Lithium batteries have four key materials: an aluminum foil, a copper foil, a separator in the middle, and the rest are electrolytes. The procurement costs of positive and negative materials, separators, electrolytes and casings are 30%, 20%, 20%, 20% and 10%, respectively.

In addition, there are many varieties of aluminum foil products used in other parts of lithium batteries, such as aluminum-plastic film for battery soft packs, tabs, and modified carbon-coated foils, electric etching foils and other products. Therefore, aluminum foil plays a crucial role in the development of new energy vehicles.

It is predicted that by 2030, the number of electric vehicles in China will account for more than 30% of the total number of vehicles.

Ø The advantages of aluminum foil used in lithium-ion batteries are reflected in the following aspects:

1. Extend the service life of lithium-ion batteries, because the special aluminum foil has better physical properties, which significantly improves the cycle performance of lithium-ion batteries.

2. To improve the consistency of lithium-ion batteries, the use of special aluminum foil can not only reduce the internal resistance, but also improve the consistency of internal resistance.

3. Improve the rate discharge performance of the battery. After the special aluminum foil is selected, the rate performance of the lithium-ion battery is significantly improved, especially in the case of a large rate (greater than 3C), the rate discharge capacity is improved by more than 15%, or at the same rate In this case, special aluminum foil can improve the energy density of lithium-ion batteries.

Ø Key points of battery aluminum foil production

Aluminum foil for lithium batteries has high requirements on alloy composition, flatness, thickness, dyne value, cleanliness, pinholes, performance, etc. At present, the domestic aluminum foil products used in the field of low-end batteries are gradually becoming saturated, while the supply of aluminum foil products for high-end power batteries is in short supply.

The application characteristics of lithium batteries and the high quality indicators of battery aluminum foil require the aluminum processing industry to take corresponding measures to produce battery aluminum foil products with excellent quality and customer satisfaction.

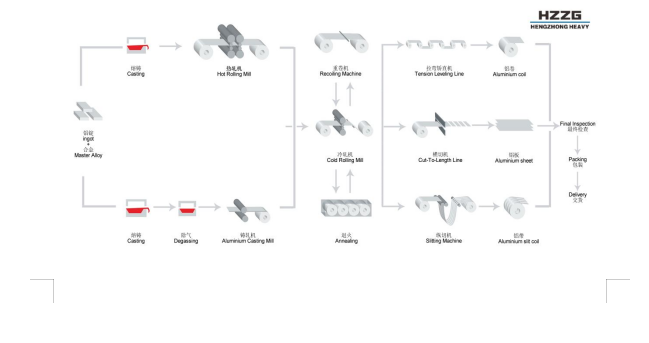

The battery aluminum foil is mainly invested in equipment, and the required equipment includes melting furnace (aluminum water), holding furnace, casting or hot rolling mill, cold rolling mill, foil rolling mill, cut to length line/slitting, etc.

Ø According to the requirements of battery aluminum foil products, the aluminum foil processing equipment provided by Hengzhong Heavy Industry has the following characteristics:

1. The cast rolling mill is equipped with on-line degassing, on-line grain refinement, electromagnetic casting and other devices;

2. The aluminum foil rolling mill equipment is equipped with advanced automatic thickness control system (AGC) and automatic shape control system (AFC) to achieve precise control of shape and thickness;

3. Aluminum Finish rolling foil blanks, strictly control the hydrogen content of the blanks, the amount of non-metallic slag inclusions and grain size, and ensure product quality from raw materials;

4. Advanced online oil removal technology is adopted to ensure the cleanliness of the aluminum foil on the basis of ensuring the mechanical strength of the aluminum foil.

The high prosperity of the downstream industry has driven the demand for battery aluminum foil to continue to rise. It is expected that the shipment of battery aluminum foil will continue to rise. However , the overall barrier of battery aluminum foil is relatively high , and the overall supply of the industry is tight, which is guided by the policy . At present, the global trend of new energy vehicles is still advancing, and my country's battery aluminum foil still has a broad market development space. Major aluminum foil manufacturers have transformed in whole or in part to the direction of battery aluminum foil. The key equipment for aluminum foil production is the rolling mill. The rolling mill equipment provided by Hengzhong Heavy Industry has great advantages in control accuracy and production efficiency. Greatly improve the yield of aluminum foil products and the stability of batteries.

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL: +008615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp : +008615188318176 Wechat : +008615188318176