- Roll Cooling Spray Systems

- Hengzhong Catalogue

- Aluminum Casting roller

- Aluminum Casting roller shell

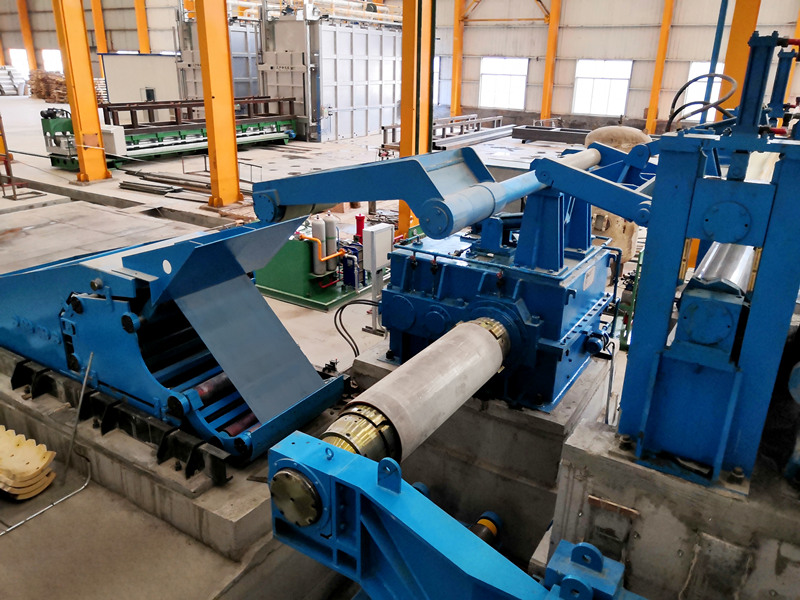

- Aluminum casting mill

- Aluminum foil rolling mill

- Aluminum Cold rolling mill

- Mold Crystallizer aluminum for continuo

- Cut to length line

- Tension leveler line

- Aluminum coil Edge trimming of rewinding

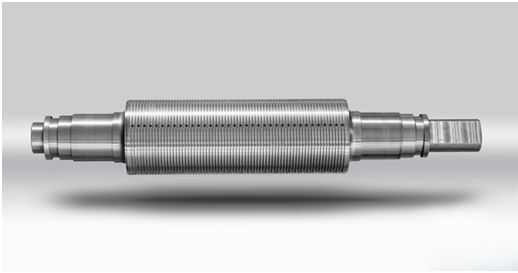

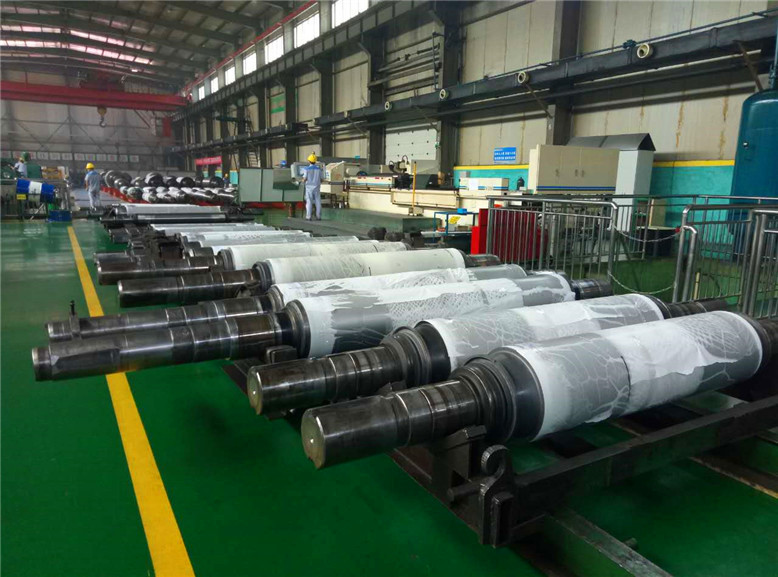

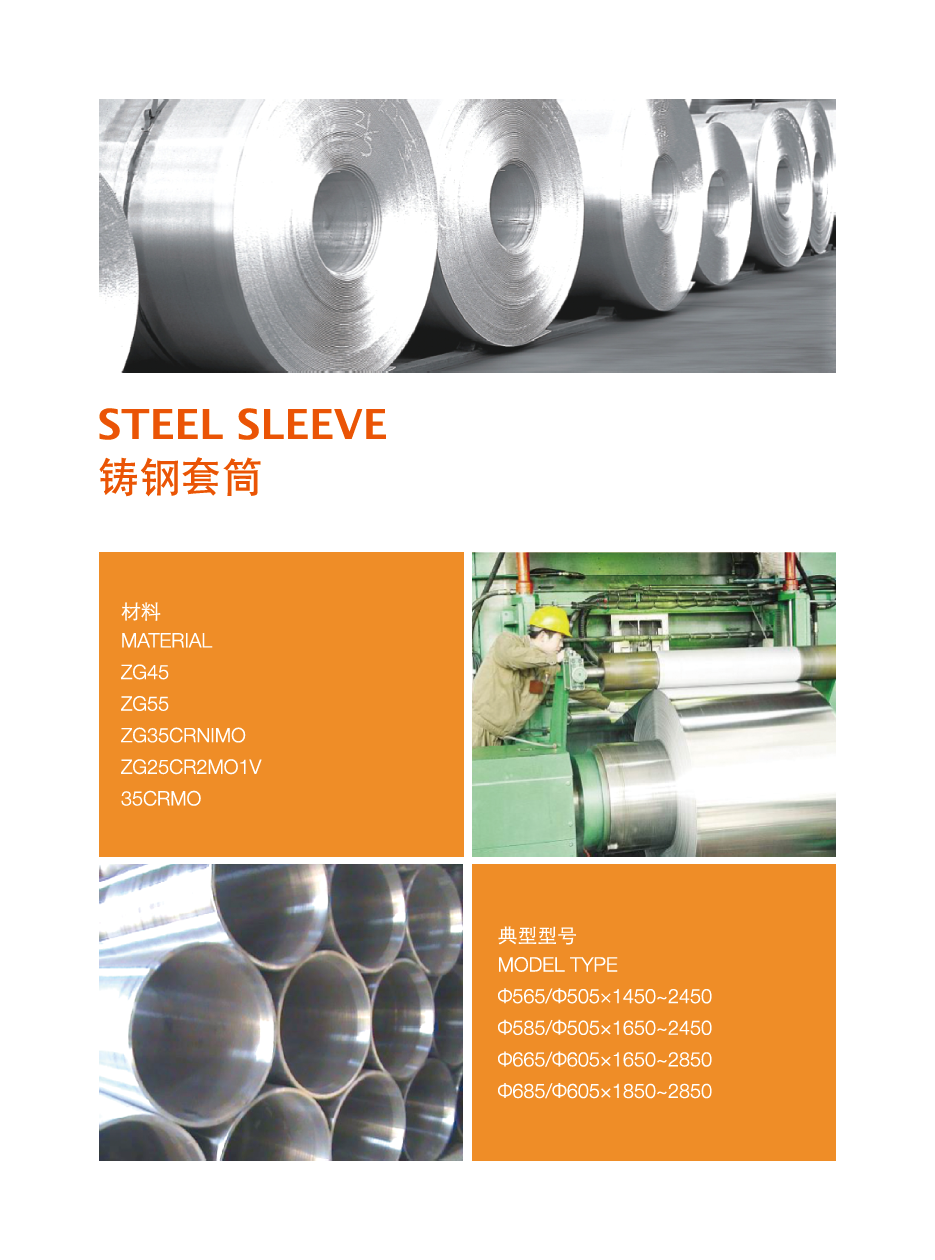

- Roll sleeve for aluminum coil

- Roller shell for cast rolling mill

- Color Aluminum Reflective sheet

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:23-03-10 Glance Over:

Ø The definition of "aluminum foil lunch box"

"Aluminum foil lunch box" is a disposable lunch box made of aluminum foil. It is a new type of catering delivery container. Compared with lunch boxes made of other materials, it has light material, high barrier properties, anti-ultraviolet rays, moisture-proof and anti-corrosion, and long shelf life . characteristics, and because aluminum can better maintain the freshness and moisture of food, it is more in line with the concept of environmental protection and health of modern people.

At present, aluminum foil lunch boxes are mostly used for the retail of aviation food, cake food, and the packaging of finished food in the takeaway industry such as supermarket roast chicken. In fact, as early as during the Shanghai APEC meeting, aluminum foil lunch boxes have become the preferred dining utensils for heads of state. During the 2008 Beijing Olympic Games, aluminum foil lunch boxes became "popular" among athletes and service personnel. It is understood that during the World Expo, the daily supply in the central kitchen for Expo employees alone was around 6,000, with a maximum of nearly 10,000.

So, for more and more applications, how to ensure the quality of aluminum foil lunch box containers?

Ø Main technical requirements of aluminum foil for lunch boxes and food containers

1.1 Alloy Selection

First of all, we generally choose aluminum series 1, 3 and 8 for lunch box and food container aluminum foil;

1.2 mechanical properties

1.3 Surface Quality

Due to the particularity of the use of aluminum foil for airline lunch boxes and food containers, the requirements for black threads (strips), pinholes, and degreasing on the surface of the aluminum foil are particularly high. There should be no obvious black threads or pinholes on the surface of the aluminum foil. After annealing in an annealing furnace, The surface should meet the requirements of grade A of the water brushing test in the GB3198-1996 standard.

Ø Production process control

2.1 Casting and rolling process

Due to the special requirements on the surface of this type of aluminum foil, high requirements are placed on the surface of cast-rolled slabs. Through the following measures to ensure the quality of billet.

l In the casting and rolling production of the casting and rolling machine, graphite spraying is changed to combustion flame spraying. On the premise of ensuring that the slab does not stick to the roll, the amount of flame should be reduced as much as possible to avoid black stripes on the surface of the slab.

l In addition to the normal casting and rolling process operating procedures, strengthen the slag removal and spray refining of the melt in the smelting furnace, increase the number of refining times in the standing furnace; control the degassing effect of the online degassing box; when installing the foam filter plate, prevent it from being damaged and the bottom Short circuit, side leakage, etc. affect the filtering effect; carefully maintain the working rolls and backup rolls of the casting and rolling mill to ensure the smoothness of the surface.

2.2 Cold rolling process

① Choose a reasonable tension parameter to avoid scratches between the layers of the aluminum coil.

②When rolling the finished product, adjust the compressed air volume of the roller cleaner to make the surface of the aluminum foil less oily.

2.3 Finished product heat treatment

Airline lunch box. Food container forming molds have high precision and clearance requirements, and strict requirements on the thickness tolerance of aluminum foil (plus or minus 5% of the nominal thickness of aluminum foil) and the range of mechanical properties. The rolling technology solution provided by Hengzhong Heavy Industry integrates mechanical actuators, electrical and automatic control systems, and practical process know-how to ensure that the surface and performance of each batch of products meet the requirements of use.

To sum up, through reasonable technological measures, our casting and rolling billets for casting rolling mills, cold rolling mills, aluminum foil rolling mills, etc. can completely produce high value-added, high requirements and can replace imported aviation products through casting rolling, cold rolling and other processes. Aluminum foil for lunch boxes and food containers.

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL: +008615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp : +008615188318176 Wechat : +008615188318176