- Roll Cooling Spray Systems

- Hengzhong Catalogue

- Aluminum Casting roller

- Aluminum Casting roller shell

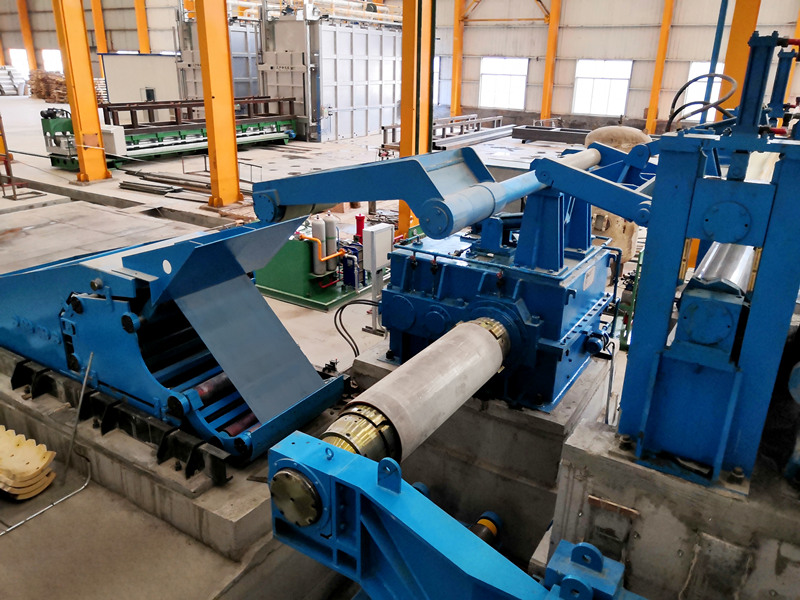

- Aluminum casting mill

- Aluminum foil rolling mill

- Aluminum Cold rolling mill

- Mold Crystallizer aluminum for continuo

- Cut to length line

- Tension leveler line

- Aluminum coil Edge trimming of rewinding

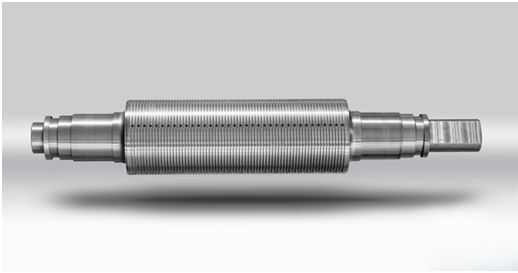

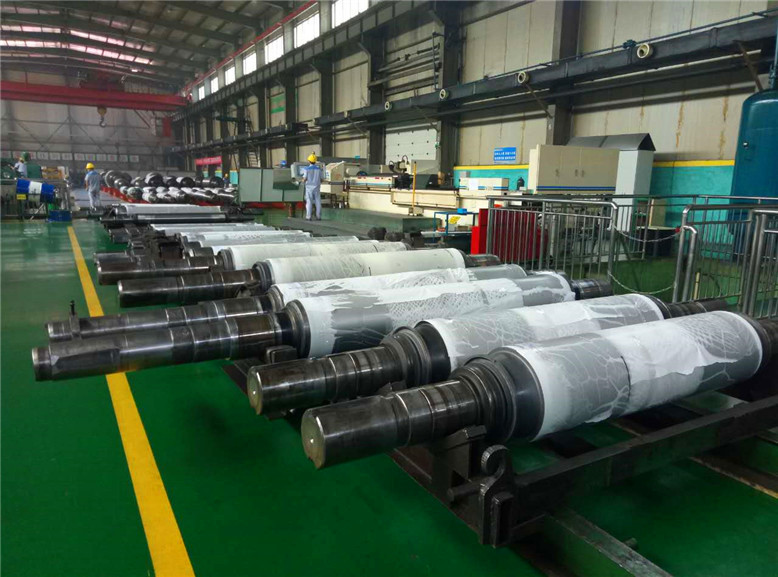

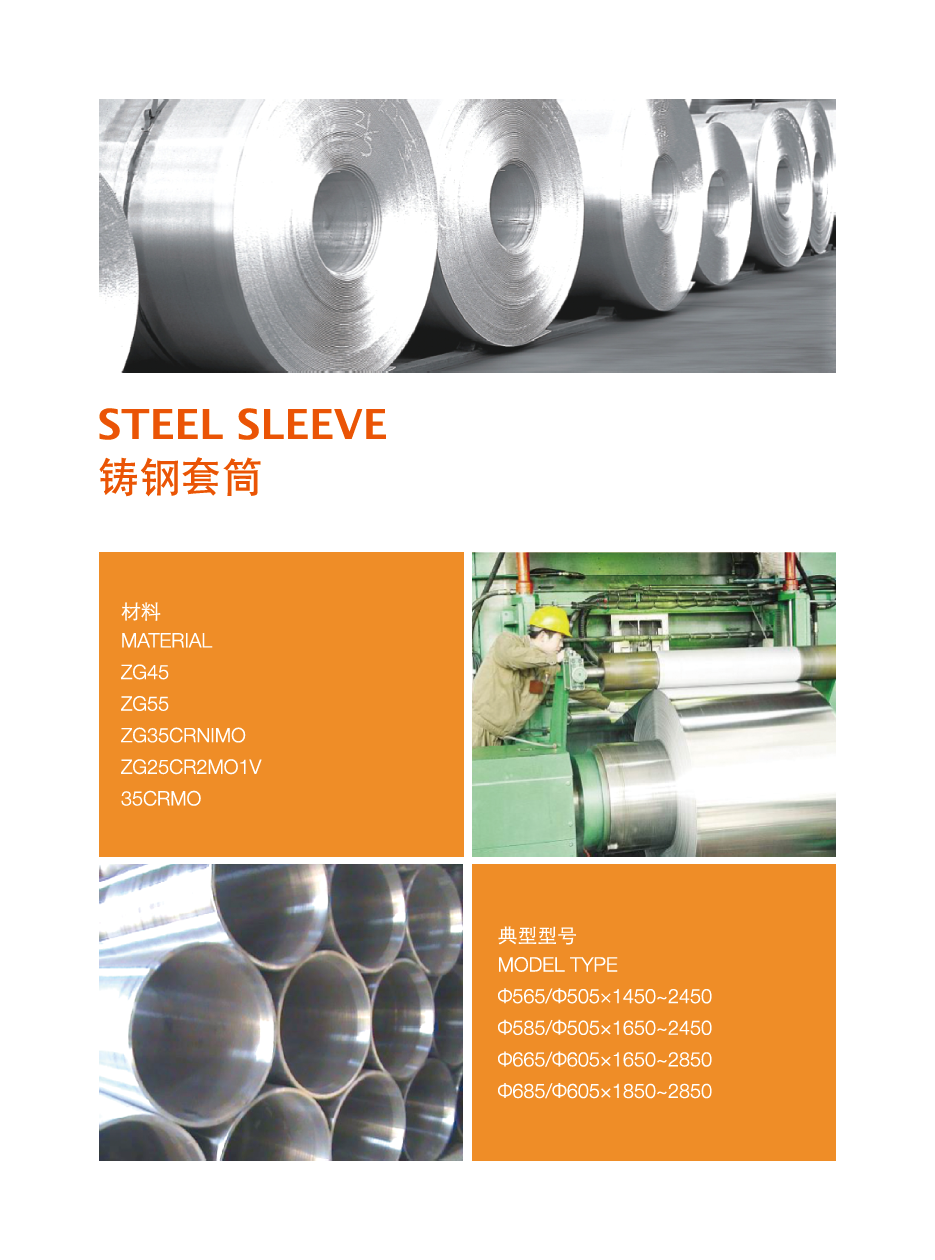

- Roll sleeve for aluminum coil

- Roller shell for cast rolling mill

- Color Aluminum Reflective sheet

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:23-09-08 Glance Over:

Aluminum for cooking utensils by hot rolling process

With the rapid development of industry in recent years, many alloy plate and strip products headed by aluminum wafers are gradually being used in various industries, which greatly promotes the growth of industry and economic development. Aluminum alloy discs show strong advantages in the manufacture of cookware, and are the deep-processing products of aluminum alloy plates and strips with the largest consumption.

Aluminum wafers refer to plate-shaped aluminum products manufactured from aluminum ingots by plastic processing methods. The manufacturing process requires processes such as ingot casting, rolling, annealing, and shearing. Aluminum alloy wafers are a quality type of aluminum sheet. Generally speaking, 1-series aluminum sheets are widely used in various fields from cookware to industrial equipment. 3-series and 5-series aluminum sheets have medium strength and good corrosion resistance, and are often used as workpieces such as cookware.

The most advanced equipment for the finished production of aluminum wafers is the aluminum wafer uncoiling and blanking production line. Such an automated production line is a fully automatic and integrated aluminum wafer production equipment. Aluminum wafers are produced by hot rolling processes from aluminum ingots, which can effectively Improve material utilization. The main equipment includes two-roll rolling mill, cold rolling mill, annealing furnace, cut-to-length line, punching machine /circular shearing machine, etc. The products are widely used in industries such as stretched aluminum wafers for cooking utensils.

From the production of aluminum discs by the hot rolling process to the manufacture of cookware, the stretching process is used. A flat metal plate will be placed over the retaining ring of the mold. The punch presses the metal sheet into the die, forming a die-like shape. The drawing tool (die, punch, etc.) on the punching press generates the load or energy required to compress the material during the punching process.

During deep drawing stamping, the material is transformed into the shape of the die. This forming is controlled by the pressure applied to the workpiece and the lubricant (deep drawing oil) applied to the workpiece or die.

Features of deep drawing parts

l Seamless parts: deep-drawn parts made of sheet metal

l Fast cycle: This method allows easy production of large quantities of products

l Complex axial geometries: deep draw drawing provides exceptional detail and precision.

l Less skilled labor: high precision can produce the same results as skilled labor

The manufacture and use of cookware such as aluminum pots constantly require aluminum alloy wafers to eliminate process defects caused by adverse factors. By continuously controlling and eliminating various defects by improving key process technology and updating equipment, the performance of aluminum alloy wafers can be improved, and the surface has a better appearance, thus providing a reliable guarantee for exquisite cookware.

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL: +008615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp : +008615188318176 Wechat : +008615188318176