- Roll Cooling Spray Systems

- Hengzhong Catalogue

- Aluminum Casting roller

- Aluminum Casting roller shell

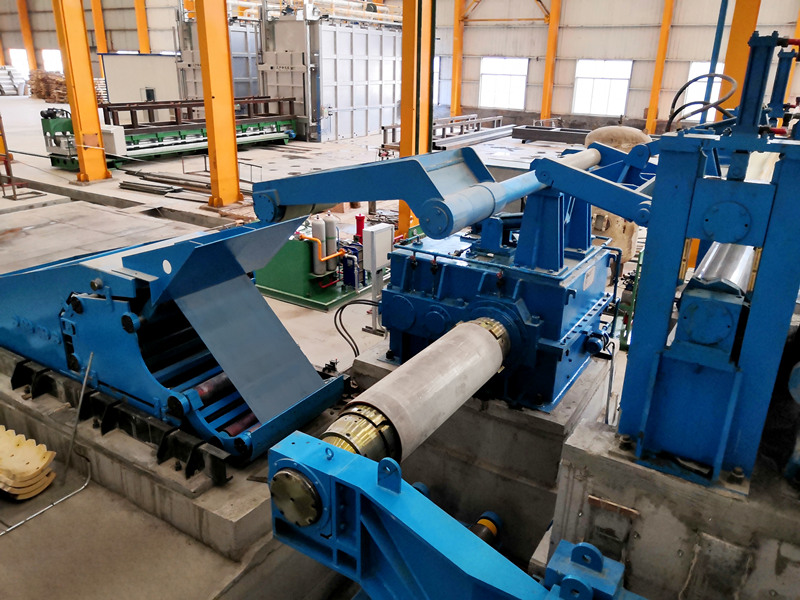

- Aluminum casting mill

- Aluminum foil rolling mill

- Aluminum Cold rolling mill

- Mold Crystallizer aluminum for continuo

- Cut to length line

- Tension leveler line

- Aluminum coil Edge trimming of rewinding

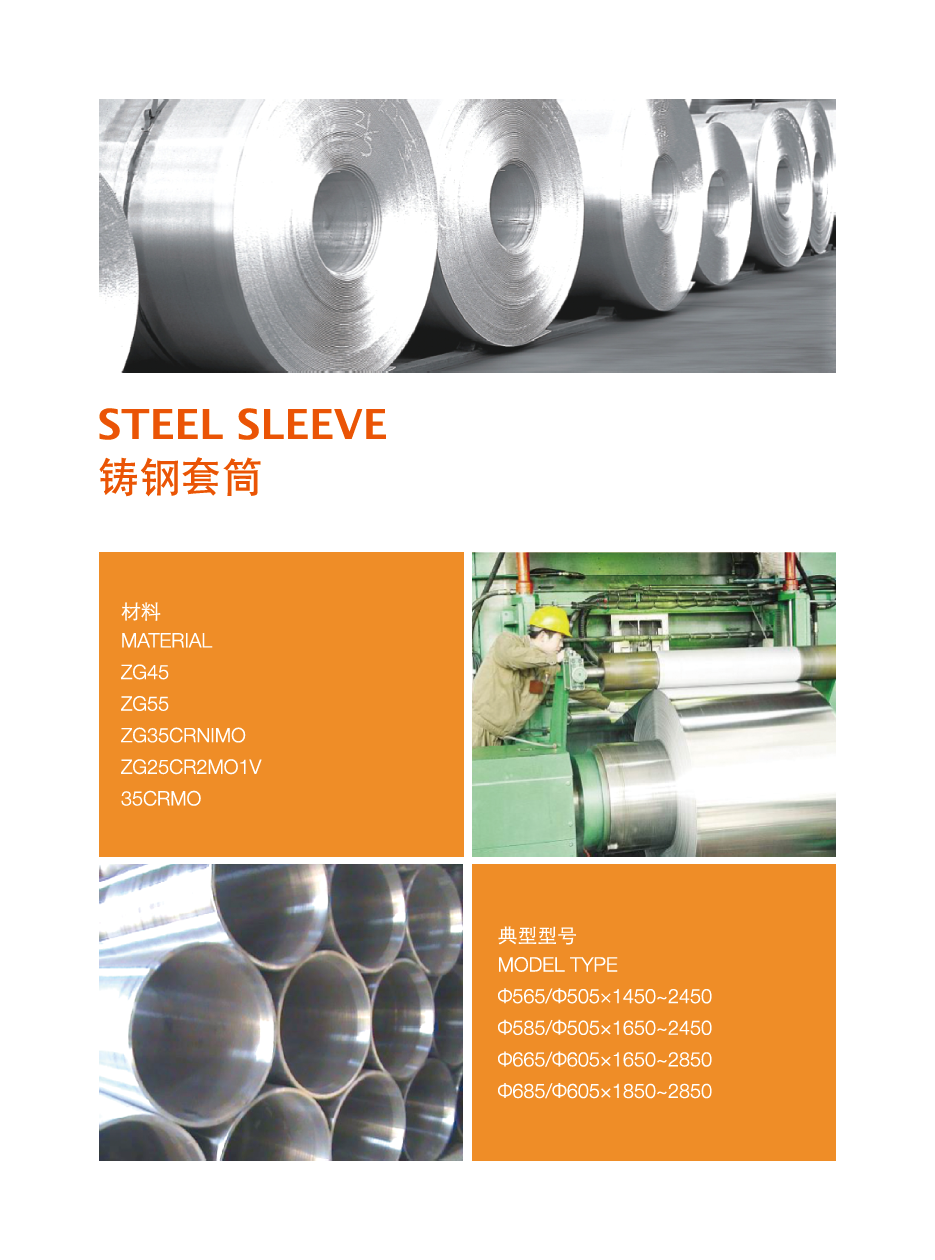

- Roll sleeve for aluminum coil

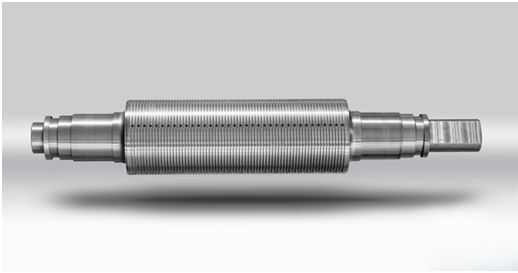

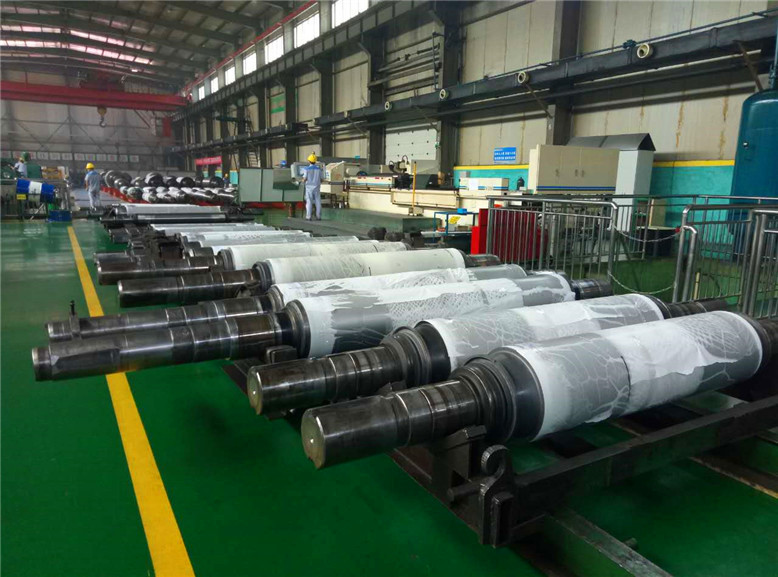

- Roller shell for cast rolling mill

- Color Aluminum Reflective sheet

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:23-09-08 Glance Over:

Aluminum for cooking utensils by casting and rolling process

According to incomplete statistics, about half of the world's cooking utensils are made of aluminum, and the heating efficiency of cooking is as high as 93%, while stainless steel and cast iron are only 1/3 of that of aluminum. Aluminum and aluminum alloy discs have the advantages of light specific gravity, good thermal conductivity, good corrosion resistance, strong density, good strength and deep drawing performance, etc. Using aluminum discs to make cookers will greatly increase the physical and chemical properties of cookers. The electrical conductivity, thermal conductivity, heat resistance and other characteristics of cookware can be better improved. Among various cookware, especially high-end cookware, the use of aluminum and aluminum alloy discs is more and more widely used, such as oil-free pans, no Blanks for aluminum cookware products such as sticky pans, pressure cookers, and compound pans.

There are many aluminum alloys for the production of aluminum discs, especially for the manufacture of high-end cookware. There are currently two types of aluminum discs for production: hot-rolled billets and cast-rolled billets. When the performance of cast-rolled billets also meets the requirements, the production cost is relatively low, which further enhances product competitiveness. The casting and rolling billet is taken as an example to illustrate:

The main equipment used in the production of aluminum wafers by the casting and rolling process includes melting furnaces, static furnaces, degassing, casting rolling mills, cold rolling mills, annealing furnaces,tension leveling line, shearing machines, etc.

The production of excellent aluminum wafer products requires continuous innovation of key technologies and production processes and updating of production equipment: strengthening of melt quality control technology in the melting and casting process; control of heat treatment process; design of high-speed automatic punching dies; Accuracy control; online degassing technology; liquid level controller; AC variable frequency motor, etc., can fully meet the requirements of the cooker market for aluminum alloy.

From the production of aluminum discs by the casting and rolling process to the manufacture of cookware, the spinning process is used. Spinning is to fix the flat or hollow blank on the mold of the spinning machine. While the blank is rotating with the main shaft of the bed, the blank is pressed with a spinning wheel or a driving rod to cause local plastic deformation.

Spinning step

l Fix the cut aluminum disc on the mandrel of the lathe machine ;

l mandrel drives the aluminum disc to rotate at a high speed, and the tool with the wheel begins to press the surface of the aluminum disc , stretching and changing the shape of the aluminum disc until the aluminum disc is completely attached to the inner wall of the mold ;

l After the molding is completed, a cutting machine will cut off the sharp edges.

In addition to cookware, many aluminum products can be spun on a lathe. Aluminum wafers are mainly used in the production of cookware, which has the characteristics of fast heat transfer, light weight, and easy recycling. Thereby, it is beneficial to the concept of energy-saving and environment-friendly production and life advocated by the state, which is conducive to improving the living environment and quality of life, and has good environmental benefits.

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL: +008615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp : +008615188318176 Wechat : +008615188318176