- Roll Cooling Spray Systems

- Hengzhong Catalogue

- Aluminum Casting roller

- Aluminum Casting roller shell

- Aluminum casting mill

- Aluminum foil rolling mill

- Aluminum Cold rolling mill

- Mold Crystallizer aluminum for continuo

- Cut to length line

- Tension leveler line

- Aluminum coil Edge trimming of rewinding

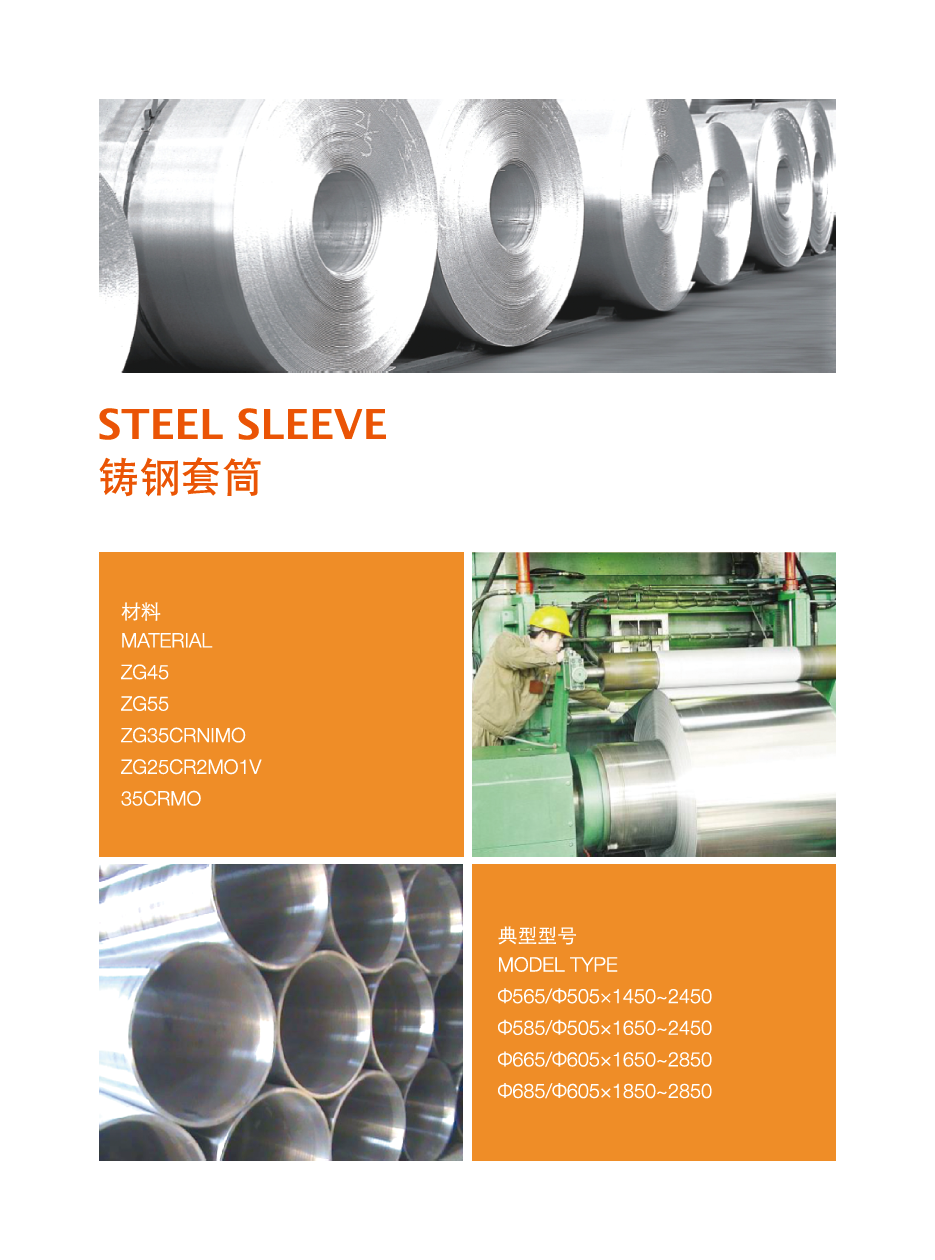

- Roll sleeve for aluminum coil

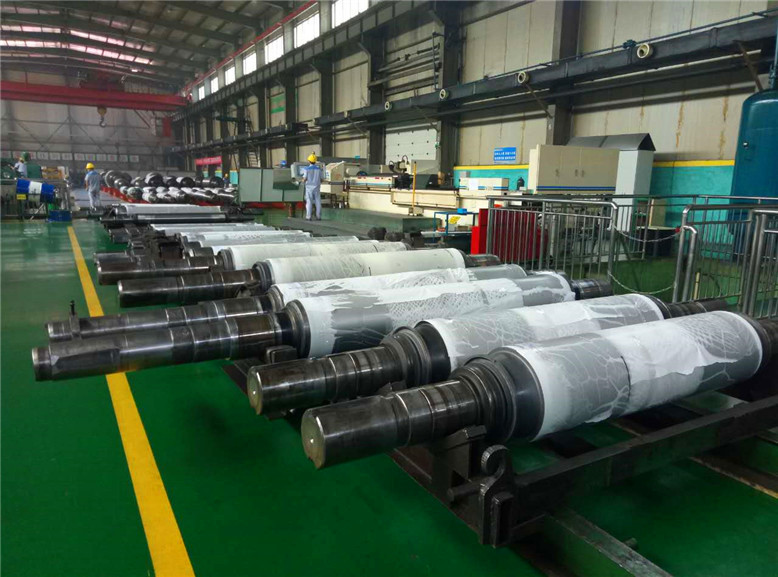

- Roller shell for cast rolling mill

- Color Aluminum Reflective sheet

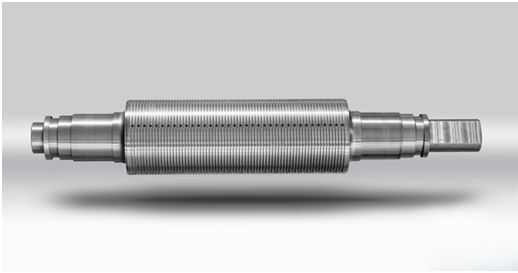

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:17-05-07 Glance Over:

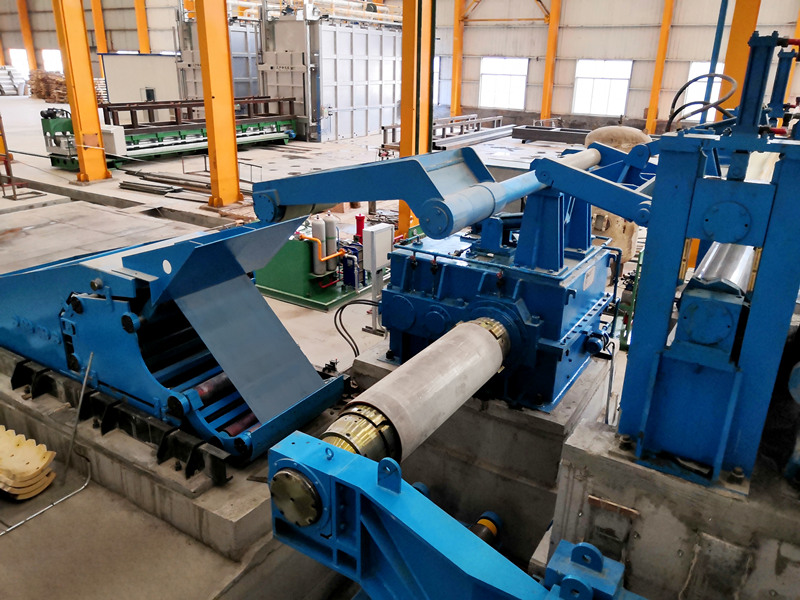

Roll changing procedure of aluminum cast rolling mill (about 210 minutes)

The roll changing is divided into two parts: first, the old roll out of the arch; the two, the new roll to promote the arch.

The first part: the roll out of the arch

1, water. Turn off the water circulating water pump and water supply valve; open the lid of the circular water cover, open the drain valve.

2, open the cover around the arch.

3, rising coupling tray, operating in the console, select the roll change mode, exit the main drive.

4, and so on, after the release of water pressure, open the four water recycling metal hose connector.

5, in the console operation, open the two frame lock pin.

6, in the console operation, the arch vertical, at the same time to observe whether there is around adhesion, don't hang up to, tubing and pipe.

7, cleaning rail health.

8, after the vertical, open the arch on both sides of the large screw, press the cylinder down, so that the roller wheel completely into orbit.

9, open the arch side of the work of the four anti displacement device.

10, in the console to roll change device to roll out.

11, when the roll back out, can use the main drive or other tools (Jack) to help out. The second part: the new roll to promote the arch

1, put the new roll on the track.

2, the pad iron and roll gap adjustment device on both ends of the lower roller, according to the needs of both ends of the roller placed under the thick steel plate.

3, put the new roll on the lower roller, the right end of the pin hole, the four corners of the pad to align, no external appearance.

4. Use vernier caliper to measure and adjust the thickness of the four angle gasket, ensure the thickness of the same, the error is within 0.2mm, roll gap adjustment to the middle position.

5, cleaning the orbital debris, hit into the console on the roll roll changing device, promote arch.

6, close the work side of the four anti displacement device.

7, cleaning the bottom of the debris, tilt arch in place.

8. Close the two locking pins to see if they are in place.

9, adjust the position of the two main drive, so that it corresponds to the corresponding roller profile.

10, to promote the main drive in place.

11, lower coupling tray.

12, put down the arch on both sides of the large bolts and tighten.

13, install the cooling water circulation metal hose and install the safety pin.

14, cover the cover.

15, close the drain valve, open the water cycle of the water supply valve.

16, start the circulating water pump, and exhaust, check whether leakage, flow and water pressure is normal.

Aluminum casting rolling mill

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL: +008615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp : +008615188318176 Wechat : +008615188318176