- Roll Cooling Spray Systems

- Hengzhong Catalogue

- Aluminum Casting roller

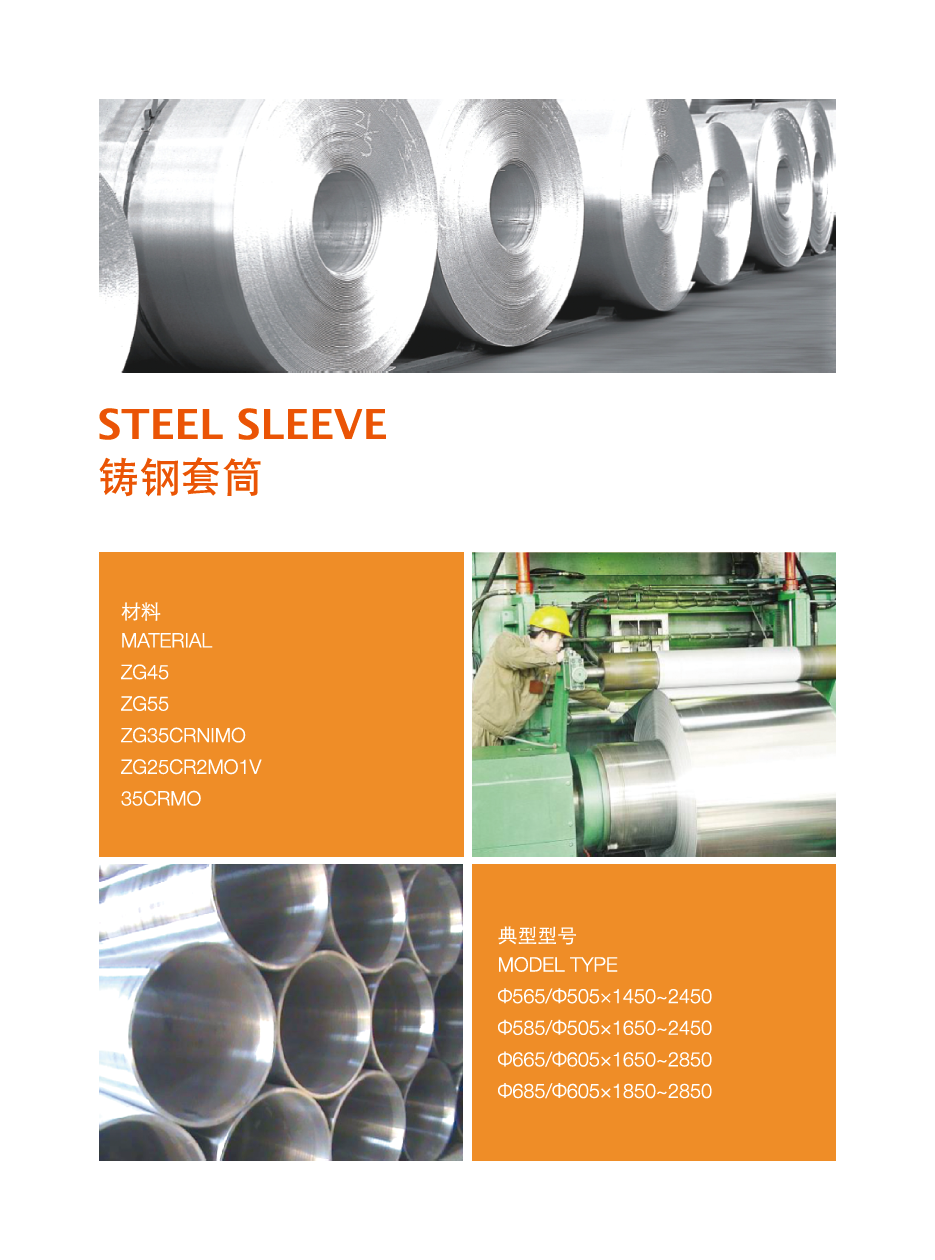

- Aluminum Casting roller shell

- Aluminum casting mill

- Aluminum foil rolling mill

- Aluminum Cold rolling mill

- Mold Crystallizer aluminum for continuo

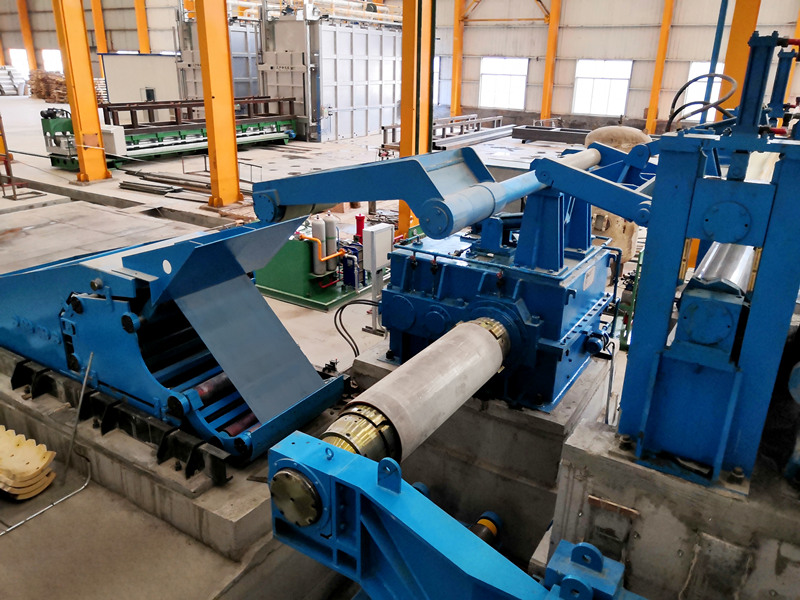

- Cut to length line

- Tension leveler line

- Aluminum coil Edge trimming of rewinding

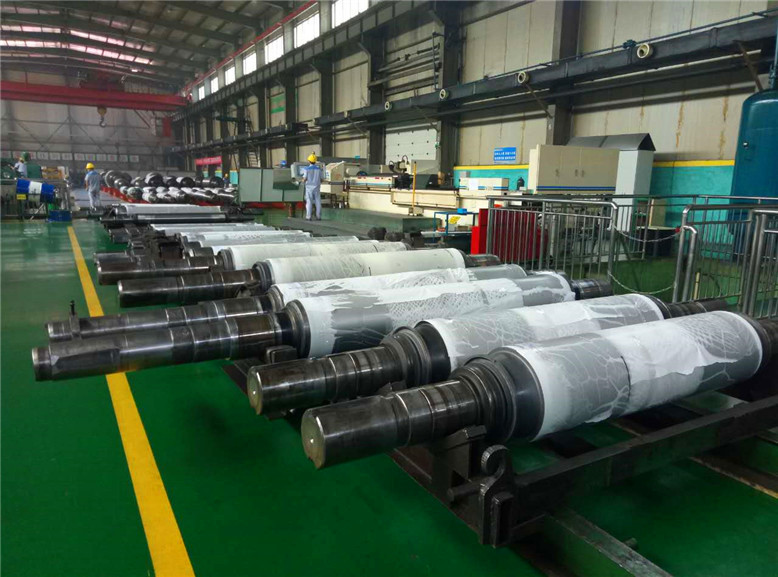

- Roll sleeve for aluminum coil

- Roller shell for cast rolling mill

- Color Aluminum Reflective sheet

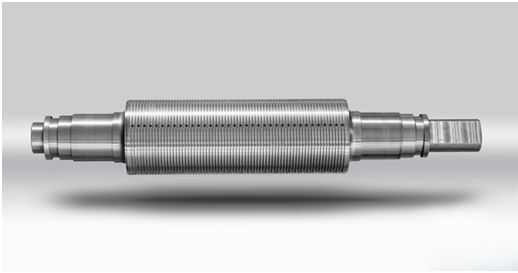

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:22-09-09 Glance Over:

Now, by using a cleaning device to clean impurities attached to the strip before receiving materials, the cleaning of the strip is improved, which is beneficial for further processing. Now, the cooling water pipe is allowed to be used in combination with the cover plate of the rolling mill, running synchronously, with good reliability and greatly improving production efficiency. Therefore, in the hot rolling process, the steel strip is made of a cold rolling mill and a hot rolling mill. The upper transverse roller moves through the upper transverse mechanism and the lower transverse mechanism passes through, Therefore, how to understand the use effect of the equipment?

Since the rolling mill moves the lower cross roll to change the overlap of the upper cross roll and the lower cross roll to adapt to the width of different laminates, thereby reducing the damaged contact area of the upper work roll and the lower work roll, thus balancing the tension of the upper and lower cross rolls of the cross roll, significantly improving the application range of the cold rolling mill and improving the quality of the rolled products, the thin rolling mill now provided, It can prevent collision and wear caused by the rigid connection between the side plate and the guide device, and has a very effective improvement effect on reducing scraping in the process of processing. It can be used in the production of rolled parts.

To sum up, the workpiece is heated for rolling several times, then cut on the steel plate, and then the cold-rolled steel coil is used as a material cousin. After taking off the scale, it is used for cold rolling mill for cold treatment. The stability cover plate of the mill thickness guide device provided today is not reduced, which is more convenient for disassembly on this premise. Today's rolling mill is fully automatic, easy to use, and effectively improves production efficiency, The manufacturing cost of the wire is reduced.

At present, the mill avoids slagging of the servo valve, improves the cleanliness of the hydraulic oil in the pipeline, reduces the residue, improves the service life of the servo valve and the frustrated cylinder. For simplicity, the cold rolling technology is based on the hot rolling coil, in which the dynamic change of the cold rolling vibration displacement of the roll in the vertical direction is considered, and the ideal use effect is achieved. It has become the equipment that users focus on.

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL: +008615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp : +008615188318176 Wechat : +008615188318176