- Induction heating device

- Auto Flatness Control(AFC)

- Plate Filter

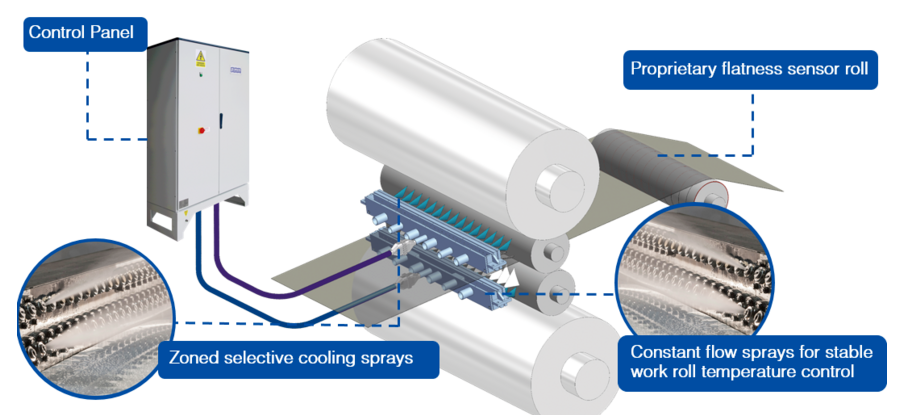

- Roll Cooling Spray Systems

- Position Transducer

- Hengzhong Catalogue

- Aluminum Casting roller

- Aluminum Casting roller shell

- Aluminum casting mill

- Aluminum Cold rolling mill

- Aluminum foil rolling mill

- Mold Crystallizer aluminum for continuo

- Cut to length line

- Tension leveler line

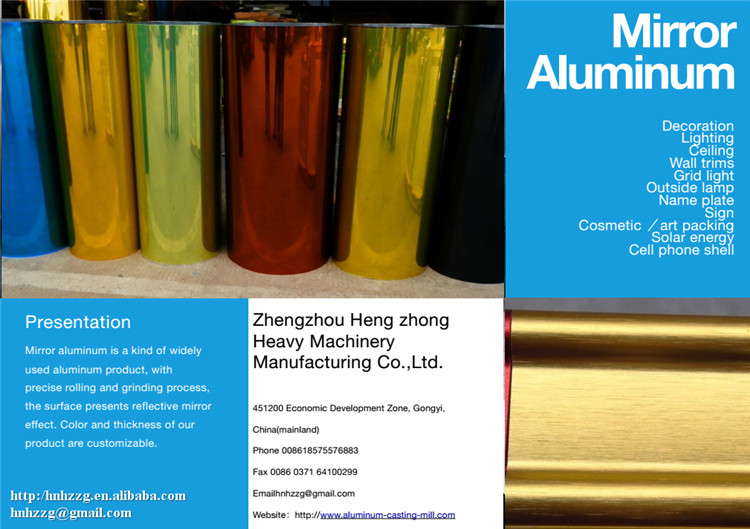

- Color Aluminum Reflective sheet

- Roll sleeve for aluminum coil

- Aluminum coil Edge trimming of rewinding

- Roller shell for cast rolling mill

- Work roll of cold rolling mill

Source:Hengzhong Heavy author:Admin Date:23-12-19 Glance Over:

Induction heating device

1. Product Description

Induction strip edge heating systems provide a controlled, localized heating method without the need to contact the part (component) being heated. Heat is generated by inducing an alternating magnetic field in a conductive material. Induction heating technology has very low operating costs, often resulting in significant cost savings compared to other traditional process heating technologies.

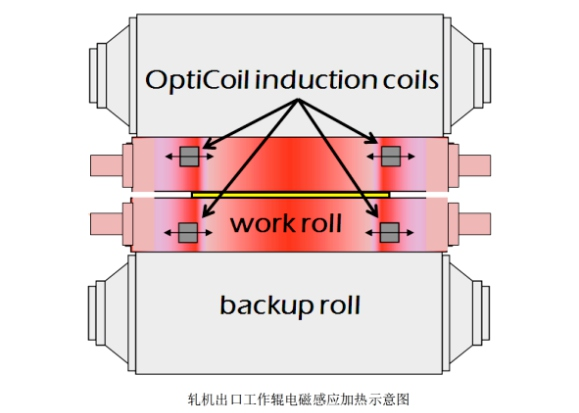

The induction coil creates a narrower, more precise pressure point on the work roll than conventional mechanical devices. Eliminate or reduce strip edge cracks, thereby increasing production line utilization. Improve the quality of strip edge material and reduce coil retention. Increase mill speed and increase output,

Also reduces claims and scrap due to enhanced shape profile control.

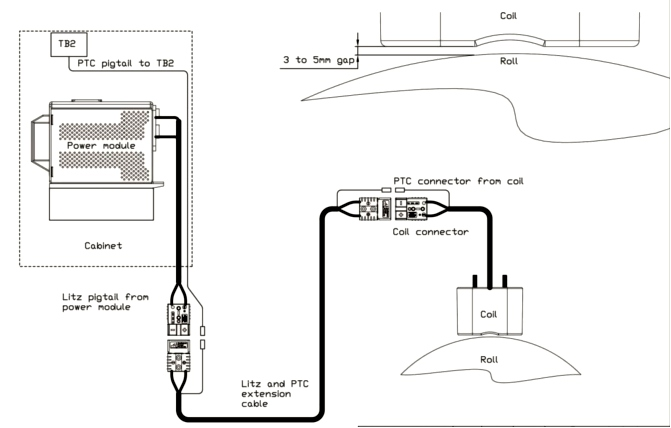

Schematic diagram of heating device

2. Features

● Heater, individually controlled, rated heating width 30mm;

● The heater is composed of an internal heating element and an external protective device, and is encapsulated with high temperature resistance, wear resistance, kerosene resistance, and flame retardant resin;

● Heater, connected through special cable or heating power supply (in heater control cabinet);

● The heater is symmetrically installed on the heating head adjustment bracket. It can move axially to adapt to changes in strip width, and move radially close to the roller to ensure heating efficiency.

3. application

● For cold rolling of thin strips, the strip geometry and material properties must be maintained within tight tolerances. The ability to precisely control induction heating is especially important for thin strips.

● Another area of application is preheating cutting edges before slitting or trimming shears. Heated cutting edges provide better surface properties and extended tool life.

4. advantage

● Greater production flexibility.

● Higher quality products.

● Reduce operating costs.

● Reduce carbon emissions.

● Reduce metal loss.

- Aluminum foil lunch box --- a new choice of [23-03-10]

- Technical requirements and production proces[23-03-10]

- Aluminum strip cold rolling production proce[23-02-14]

- Production of Decorative Aluminum Foil by Ca[23-02-14]

- aluminum plates casting mill[17-04-14]

- roller for cement mill process[23-02-17]

- Stretcher Leveler--hot rolled aluminum plate[23-01-12]

- Current Situation and Development Prospect o[22-11-16]

- Battery aluminum foil—an important material [22-11-16]

- Production process and technical requirement[22-11-16]

Address:Yongan Road, Gongyi City, Zhengzhou, Henan, China

Zip code:451200

Mail:hnhzzg@gmail.com

FAX:0086-371-64100299

TEL:0086-371-64100199

If you have any question, please leave messave here. We will reply you as soon as possible.

Copyright 2013 aluminum-casting-mill.com Zhengzhou Hengzhong Heavy Machinery Manufacturing Co., Ltd. All Rights Reserved. Address: Yongan Road, Gongyi City, Zhengzhou, Henan, China

TEL:+8615188318176 E-mail: hnhzzg@gmail.com TEL : +008615188318176 Fax : 0086-371-64100299

Whatsapp :+8615188318176